Houses made in the 1970s and 1980s are still intriguing for various house hunters. They have sturdy structures and a classic vintage look that appeals to most people. Another thing adds to their value: Apart from their robust structure they use cast iron plumbing systems in their vicinities.

What is cast iron plumbing?

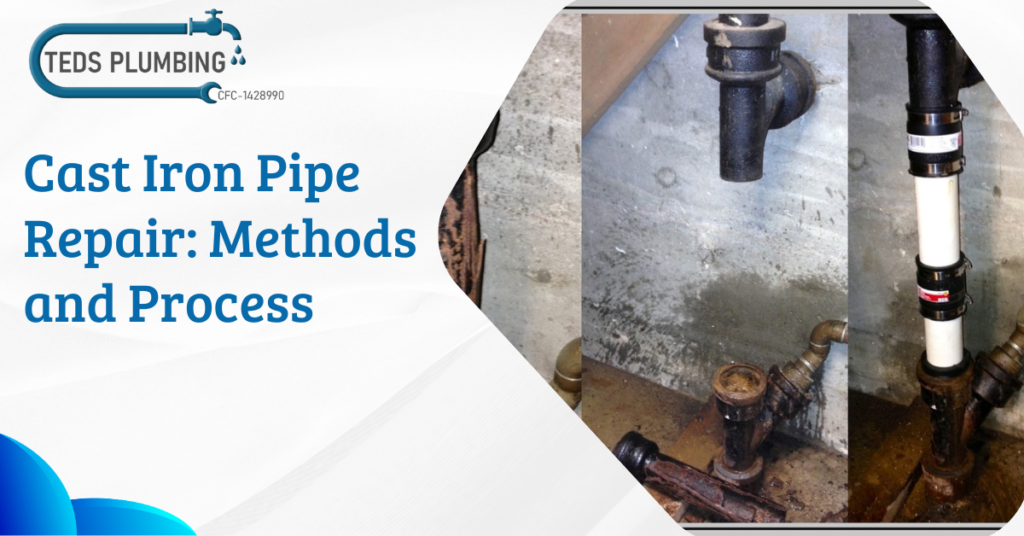

Cast iron (CI) pipes were widely used for transporting water and sewage before plastic pipes were invented. Sewer drainage uses cast iron pipes worldwide specifically DWV systems (Drain, Waste, and Vent). You will find these pipes in older homes built before the 1970s (early 1980s in some places).

Back then, builders favored cast iron pipes because of the material’s durability ability to handle water and resistance to damage. Cast iron is one of the oldest piping systems today and is now replaced by high density polyethylene (HDPE) and polyvinyl chloride (PVC) pipes. Some cast iron vent pipes are still working but most have deteriorated and need replacement.

What Are The Advantages Of Cast Iron Plumbing?

Cast iron pipe linings are regulated in multiple states because of their benefits and long lasting results. Although they are not used in most houses today, they can be seen installed in older houses.

Some of its diverse advantages are as follows.

Durability

Iron soil pipe fittings are made to last for at least 100 years. It does not damage with water damage or withstand massive earthquakes as well. Even with time, the rust creates a foam around the pipes that slows down the corrosion because of its thick walls. If the installations are made with soil, they would rather have less life. However, using sand, cast iron pipes can last longer, typically up to 100 years.

Fire Safety

Cast iron is a strong raw material that can withstand many elements, especially fire. For this reason alone, it was preferred in the past. This is the best choice for sturdy plumbing systems in areas where houses and buildings are prone to fire or other natural disasters.

Noise Reduction

Because these iron pipes don’t create the sound of water flowing or other things over them, they are a classic choice for people who do not like messy or noisy appliances or pipes in their surroundings. However, for multi story buildings, cast iron pipes can help install noise free plumbing linings.

Recyclability

Cast iron fittings are 100% recyclable. At the end of its use, it can be melted down and transformed into new products, which helps reduce waste and supports sustainable construction practices. Moreover, it can also reduce the adverse effects of harmful chemicals on planet Earth.

Minimal Expansion and Contraction

Cast iron pipes show minimal expansion and contraction with temperature changes compared to other materials. This stability helps prevent leaks and maintain structural integrity over time. However, it is the perfect choice for locations where people face extreme hot or cold weather.

These are a few advantages of installing cast iron pipes in your house or office’s plumbing system. They are environmentally friendly and maintain a pleasant water temperature. These pipes were famous for multiple reasons in the past; however, every good thing also has disadvantages.

Disadvantages Of Cast Iron Pipes

Cast iron was once a durable and reliable material used by almost all professional plumbing services. However, in today’s guide to plumbing services, the use of cast iron has become a forgotten story. Strangely, a contractor’s favorite material is not used anymore in homes or offices. There are a few reasons why people start avoiding cast iron pipes.

Some of the disadvantages are as follows.

- Corrosion: The first con of cast iron is that it’s prone to deterioration and corrosion. Rust starts developing in the pipes, and after a while you need to change the complete pipe linings because of rusty water and a weird stench coming into the drinking water.

- Heavy Weight: It is made of iron, which is quite heavy and can cause a headache while installing or maintaining the process. Its weight can also cause sinking in the ground and lead to massive cracks in the system.

- Sewer Back Into Homes: The biggest problem with cast iron pipes is that, with time they start mixing drinking water back into the plumbing system. This contaminates drinking water and causes massive health hazards for the people living in the building. This also allows pest infestations and mold growth in the pipes around the house.

- Expensive Repairs: You cannot remove one pipe or patch the faulty one while repairing cast iron pipes. You have to dig all the pipes and replace the entire system. It can be quite expensive and messy for homeowners who want to avoid it at all costs.

- Insurance May Not Cover Repairs: Check your homeowners policy for specific exclusions. Sometimes, they may be required to fix the issue but not always. Litigation seems to be ongoing about this issue.

The construction style has changed a lot in the past few years. Once an all time favorite material for plumbing, it has become the least used because of its multiple perks and repercussions to the homeowner. Cast iron plumbing can still be beneficial in a few locations. However, PVC pipes have taken their place worldwide as they are cheap, reliable and easy to install and replace.

Owning a house with cast iron pipes and looking for a company to maintain them effectively? Visit Ted’s Plumbing and receive a team of experienced plumbers at your doorstep now. Our Ted’s Plumbing Company can install and repair cast iron and PVC pipes with the same durability and provide tips for long lasting results. Visit our website today and get those pipes fixed now!

FAQs

What era has seen the popularity of cast iron pipe lining?

Cast iron pipes were popular for plumbing systems from the early 1800s until the 1970s, some houses also used these pipes in the early 1980s.

What are the commonly used materials for plumbing systems?

PVC, PEX, Copper, and CPVC are the most common materials used in modern plumbing systems in houses and offices.

Is cast iron expensive?

Cast iron itself is not super expensive. However, cast iron pipes can be costly to install due to their weight and the potential difficulty of working with them.