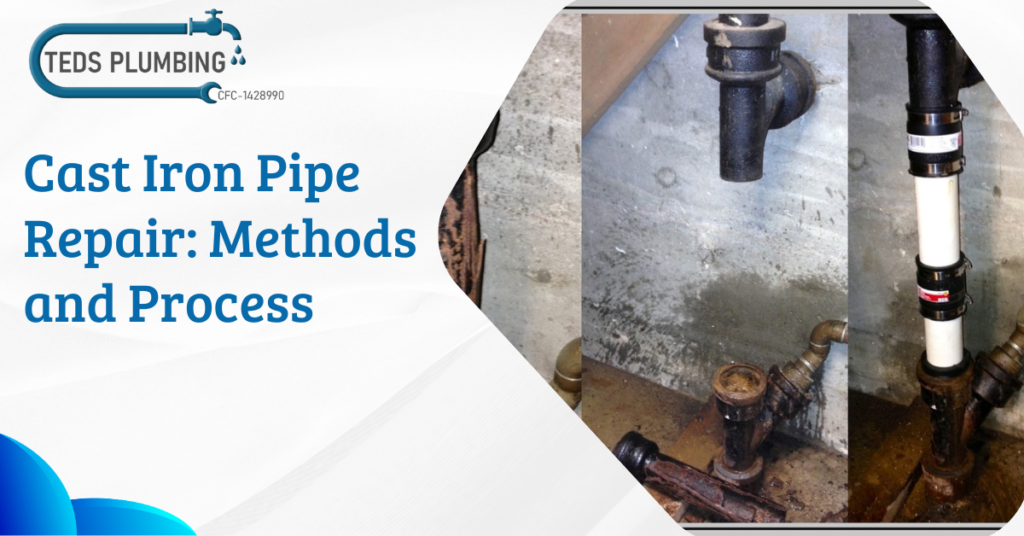

Cast iron plumbing stands out among reliable plumbing materials because of its durability and longevity. Widely used forged iron pipes in residential and business buildings have been a staple within the plumbing enterprise for hundreds of years. Due to its robustness and enduring nature cast iron has been a cornerstone of the industry.

How Long Does Cast Iron Plumbing Last?

The expected lifespan of Cast iron plumbing is typically between 75 and 100 years although it can vary based on several environmental and maintenance factors. This impressive durability stems from cast iron’s inherent resistance to degradation and robust nature which allows it to withstand high pressures and harsh conditions.

Nevertheless, with attentive care and periodic inspections it can serve a building effectively for many decades making it a worthwhile consideration for long term plumbing solutions for that purpose knowing the pros and cons of cast iron plumbing is also crucial. Let’s discuss key factors that affect the lifespan and their maintenance tips:

Key Factors Affecting Lifespan

The lifespan of cast iron plumbing is influenced by several critical factors that can either extend or shorten its effective service years. Understanding these factors can help in maintaining the integrity and functionality of these plumbing systems:

- Quality of Installation: Proper installation is crucial for ensuring the maximum lifespan of the pipes. Incorrect installation can lead to premature failure.

- Environmental Conditions: The local environment, including soil chemistry and climate can affect how long these pipes last. Areas with high humidity or corrosive soil may see shorter pipe lifespans due to increased corrosion rates.

- Maintenance Practices: Regular maintenance such as cleaning and inspecting for signs of wear or damage can significantly extend the life.

- Water Quality: Water with a high mineral content or acidity can accelerate corrosion and scale buildup inside the pipes.

- Usage Patterns: The amount of use and the type of waste that passes through the pipes can impact their longevity. Commercial or industrial use for instance may lead to faster deterioration than typical residential use.

Maintenance Tips For Longevity

To maximize the lifespan of your cast iron plumbing consider the following maintenance tips:

- Regular Inspections: Have a professional plumber inspect your cast iron pipes every few years to identify potential issues before they become severe.

- Immediate Repairs: Address any leaks or damage immediately to prevent further deterioration of the plumbing system.

- Water Treatment: If water quality is poor consider installing a water softener or filtration system to reduce pipe corrosion.

Trust Experts!

By understanding these factors and implementing regular maintenance, you can ensure that your cast iron plumbing remains functional for as long as possible potentially extending its service life beyond the average expectancy. At Ted’s Plumbing Company we specialize in providing top quality plumbing solutions and can help you assess whether cast iron is the right choice for your needs. Whether you need installation, maintenance or repair rely on Ted’s Plumbing for expert service.

FAQs

What are the signs that cast iron plumbing needs replacement?

Signs include visible rust or corrosion, leaks frequent clogging and a noticeable decrease in water pressure which indicate the deterioration of the pipes.

Is cast iron plumbing more durable than modern materials?

Yes, it is generally more durable than many modern materials like PVC especially regarding withstanding high pressures and resistance to physical impacts.

Can the lifespan of iron plumbing be extended?

Yes, regular inspections, immediate repairs of any damages and water quality management can significantly extend the lifespan of plumbing systems.